Milk is one of the most versatile agricultural products, consumed daily in households across the world. However, raw milk has a short shelf life and must be processed to ensure safety, quality, and extended usability. By converting milk into different products, farmers and businesses can increase profitability and meet diverse consumer demands.

Milk processing begins with collection and chilling. Fresh milk is quickly cooled to below 4°C to prevent bacterial growth. The next step is pasteurization, where milk is heated to a specific temperature to destroy harmful microbes without affecting nutrition. In large-scale operations, milk is also homogenized to break down fat globules, ensuring a smooth and uniform texture.

Processed milk can then be packaged and sold as toned, double-toned, or full-cream milk depending on fat content. Packaging in bottles, pouches, or cartons adds convenience and improves shelf life.

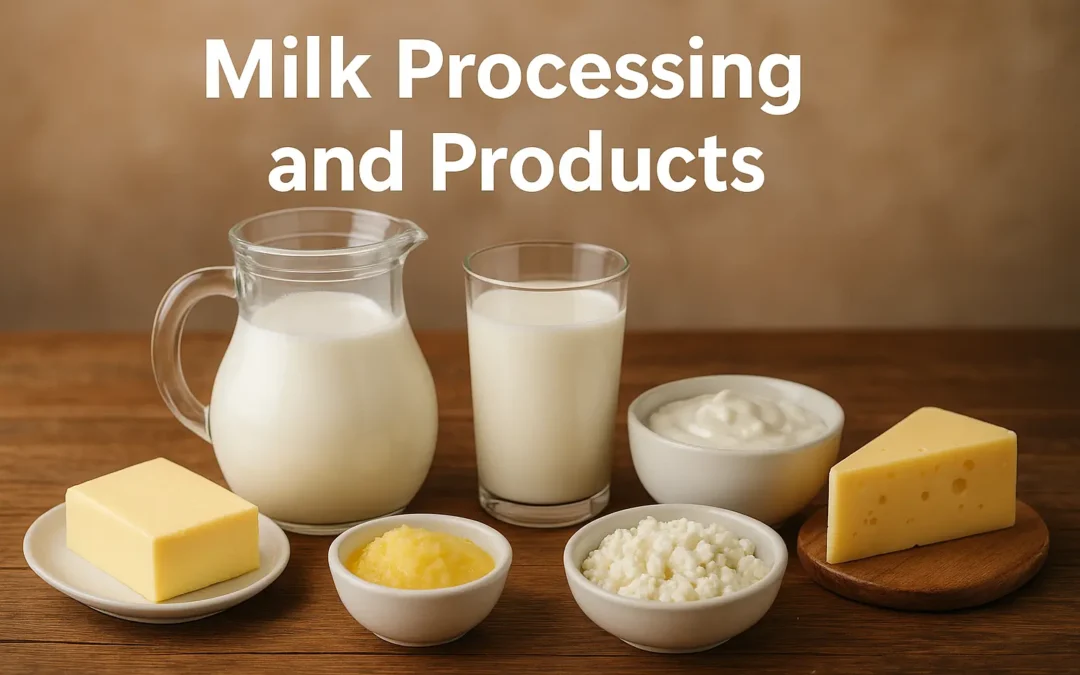

Beyond liquid milk, the dairy industry thrives on value-added products. Popular items include:

Butter and Ghee: Traditional staples with long shelf life and strong market demand.

Cheese: A high-value product with increasing popularity in urban and international markets.

Yogurt and Curd: Probiotic-rich and widely consumed for their health benefits.

Milk Powder: Essential for areas lacking fresh milk supply and for industrial use.

Ice Cream and Sweets: High-profit products, especially in growing consumer markets.

For farmers and entrepreneurs, focusing on dairy products reduces waste and ensures better returns compared to selling raw milk alone. With proper training, equipment, and hygiene practices, small-scale producers can also tap into local demand for processed dairy goods.

In conclusion, milk processing not only ensures food safety but also opens new opportunities for innovation and business growth, making it a crucial pillar of modern dairy farming.